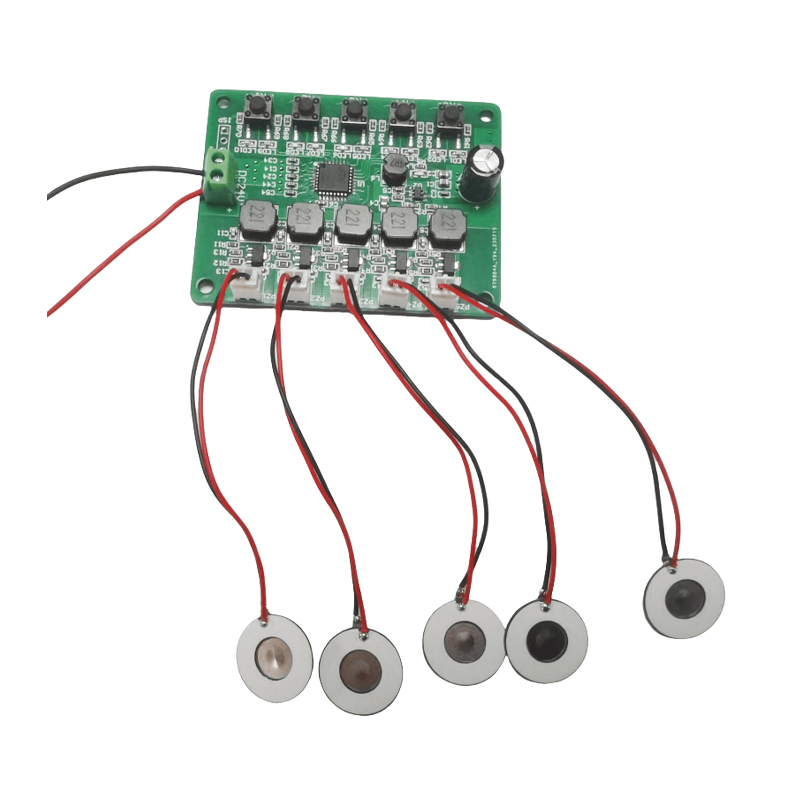

工作原理 超声雾化传感器

超声雾化传感器通过超声波的高频振动将液体转化为细雾颗粒或气泡。与传统的超声清洁设备不同,超声雾化传感器的工作原理强调了对液滴尺寸的精细控制,从而使它们在显微镜水平的物体表面上更有效地分散。这种有效的雾化过程不仅使清洁过程更加均匀,而且还可以减少清洁过程中的能源消耗,并提高整个清洁过程的效率。

超声雾化传感器的优势以提高清洁效果

1。增强清洁覆盖范围

传统的超声清洁设备通常依靠声波的振动来产生压力差,从而实现对物体表面的清洁。但是,由于声波的渗透深度有限,某些复杂形状的表面可能不会完全清洁。超声雾化传感器将液体转换为极为细的雾颗粒,它们可以均匀地覆盖物体的每个角落,从而达到更全面,更有效的清洁效果。

2。减少液体废物

超声雾化传感器可以均匀地以雾化形式分配液体,而不是传统的喷涂或浸泡方法。这种有效的液体使用方法不仅可以节省清洁液体的消耗,而且还降低了环境污染并提高了资源使用效率。

3。适用于复杂的表面清洁

在许多工业应用中,清洁物体的表面是复杂且细致的,传统的超声清洁设备可能不会完全消除隐藏在微小间隙中的污垢。超声雾化传感器可以产生较小的液滴。这些微小的液滴可以渗透到物体表面上的复杂纹理和缝隙中,从而有效地去除微小的颗粒和污染物,从而确保清洁度并且没有死角。

4。减少清洁时间

在有效清洁过程中,超声雾化传感器可以加速液体和物体表面之间的反应,从而大大减少了清洁所需的时间。与传统的超声清洁方法相比,超声原子化技术可以在较短的时间内完成相同或更有效的清洁任务。

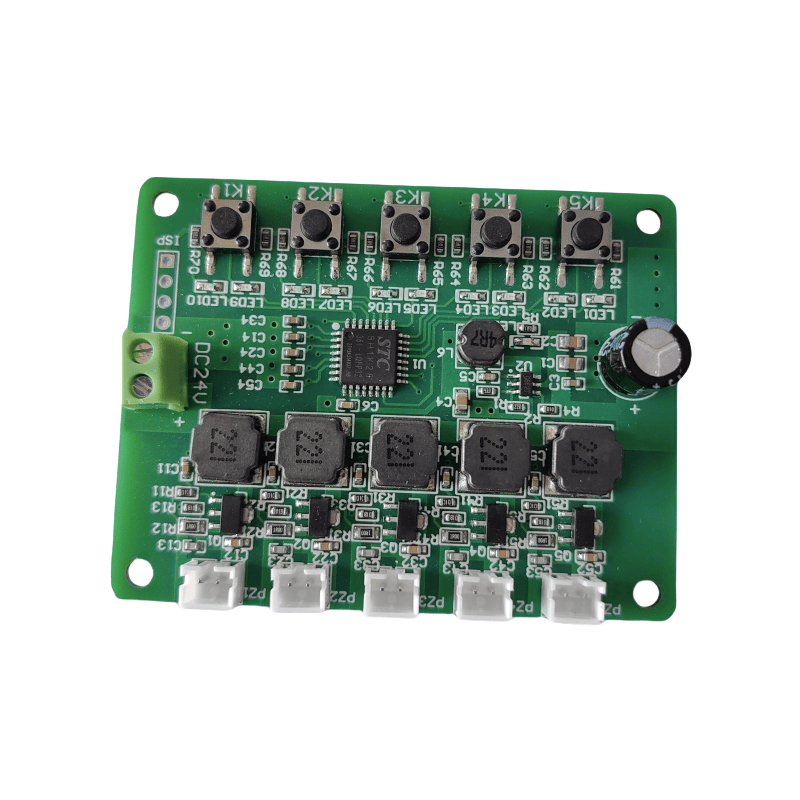

超声雾化传感器在工业清洁中的应用

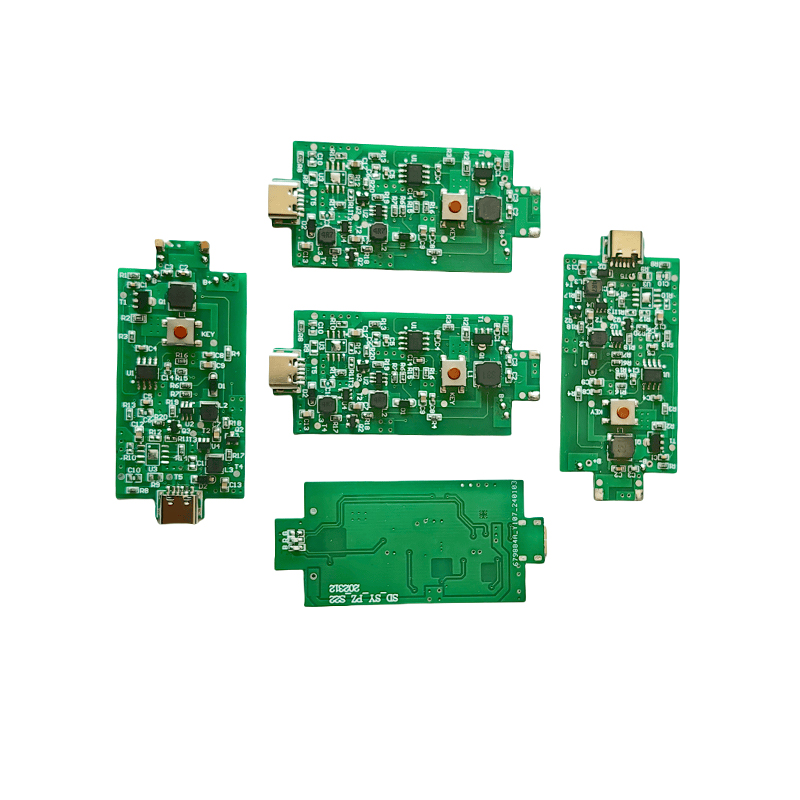

1。精密电子设备清洁

在电子制造业中,精确零件的清洁至关重要。传统的超声清洁可能会因过度振动而损害敏感的电子组件。超声雾化传感器可以通过更温和,更精确的雾化过程避免此问题,同时确保电子组件的表面不受影响,并改善设备的整体性能和服务寿命。

2。清洁医疗设备和实验室设备

医疗行业对设备卫生有极为严格的要求,尤其是在清洁外科手术器械和实验室设备方面,任何微小的污染物都可能带来严重的后果。超声雾化传感器可以很好地去除微小的污染物和细菌而不会损坏设备,从而提供更安全,更有效的清洁解决方案。

3。清洁汽车制造业的零件

在汽车制造中,发动机和传输系统等零件通常需要高精度清洁。传统的清洁方法可能无法有效去除油和微小的颗粒。超声雾化传感器可以通过其精确的液滴雾化和有效的清洁能力从这些复杂组件中迅速从这些复杂组件中清除污垢,从而确保组件的高质量制造。

4。精密光学和镜头清洁

精确的光学设备和镜头的表面通常非常细腻,任何微小的污渍或灰尘都可能影响设备的有效性。通过使用超声雾化传感器,清洁过程变得更加精致,并且可以去除镜头表面上的微小杂质,并可以去除光学成分,以确保设备的最佳性能。

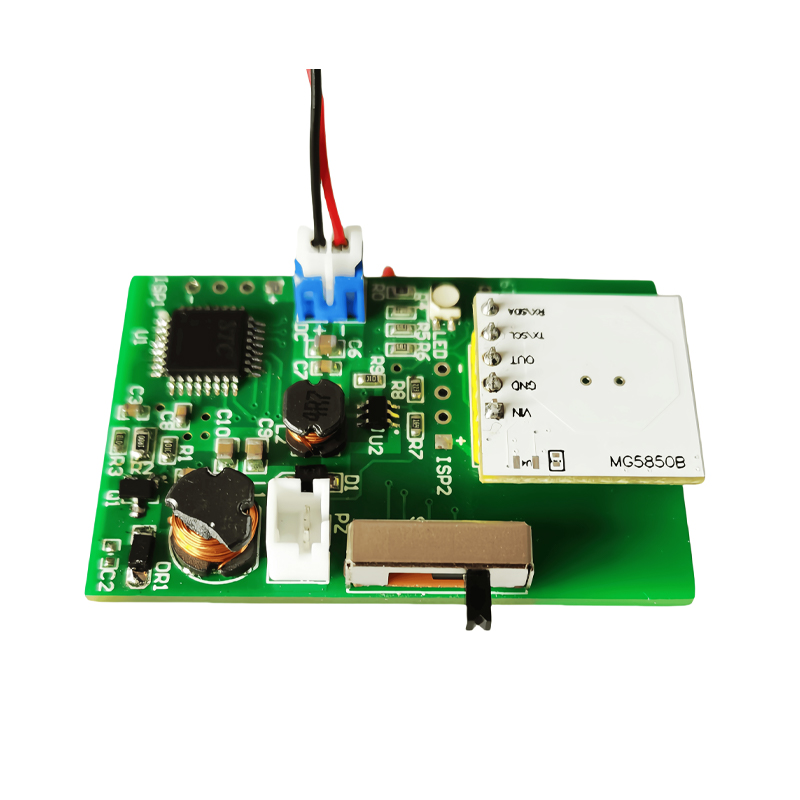

未来前景:超声原子化传感器的广泛前景

随着工业制造技术的持续创新,超声清洁技术也在不断发展。超声原子化传感器的引入为许多行业提供了更有效,环保和经济的清洁解决方案。它在精确设备清洁,表面处理和其他领域的应用表明了其巨大的潜力。

预计将来,超声原子化传感器技术将得到进一步改进,不仅要广泛用于工业领域,而且还可以与其他高级技术(例如自动化控制和智能管理系统)相结合,以进一步提高工业清洁效率和质量。此外,随着全球对环境保护和资源保护的关注,超声雾化传感器技术的低能消耗和高效率特征也将成为其在未来市场竞争中的重要优势。

English

English  中文简体

中文简体